It enables us to fabricate objects which are much larger than the size of the printer.

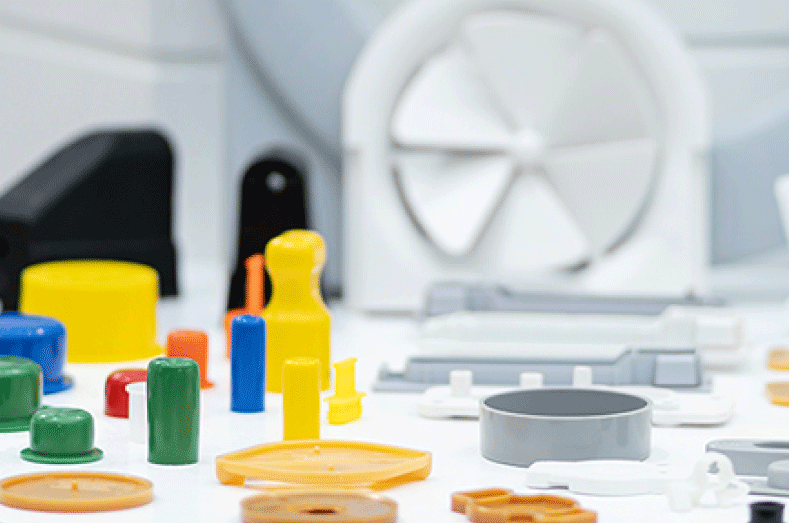

However, in recent years, researchers from the Singapore University of Technology, in collaboration with Nanyang Technological University, came up with a solution of reverting to the original shape by using VeroWhitePlus and TangoBlackPlus.Īctive materials such as shape memory polymers are used to create a solid shape which, when activated in a controlled manner, changes its present shape to another required shape and returns to its original shape. However, the ability to reverting to its original shape (self-assembly technology) was a challenge that involved human intervention. In 4D Printing, an additional “D” (dimension) is added, which is “Time.” A revolutionary change brought in 4D Printing over 3D Printing is its capability of changing shape over time due to the application of controlled impact of external sources like pressure, air, heat, water, etc. Even complicated shapes can be produced with minimal material using 3D Printing than a traditional method. 3D printing or additive manufacturing is the process of laying layer over layer until a 3-dimensional object is created from a digital file. 3D printing technology is available for the past 30 years now. TED professor Skylar Tibbits first introduced the term 4D printing in his speech at the MIT Conference in February 2013.ĤD Printing is an improved version of 3D Printing. Technical experts are conducting continuous research and development to improve efficiency. New emerging technologies are enhancing the manufacturing speed, minimizing the cost of industrial processes, etc.

Rapid enhancement to the existing technologies is helping every industry to change their working style.

0 kommentar(er)

0 kommentar(er)